Carbon Steel YZP Class 4.8 8.8 Sleeve Anchor Bolt With Hex Flange Nut

What is sleeve anchor?

The sleeve anchor,also called Dyna-Bolt, Sleeve-All, Power Bolt, and Thunder Sleeve is a type of fastener used to secure objects to a concrete or masonry structure. They can be used to join two or more concrete structures, or to fasten an object such as a shelf to a brick wall. Sleeve anchors are also referred to as two-step bolts or anchor bolts in some areas.

The sleeve anchor consists of a solid metal screw or stud with a cone-shaped tip that flares out to the sides. A metal sleeve wraps around the outside of the stud, allowing the tip of the stud to extend out the end of the sleeve. A washer and nut sit at the top of the bolt for adjustment and installation. Once the sleeve anchor has been inserted into concrete, installers turn the nut to pull the stud up into the sleeve. As the flared end of the stud passes into the sleeve, it causes the sleeve to expand outward and grasp the concrete for a secure hold.

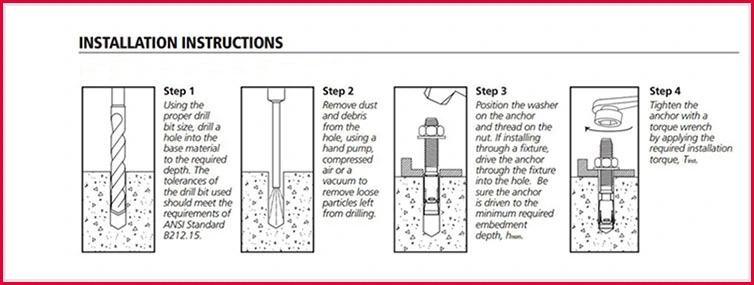

Installation Instructions

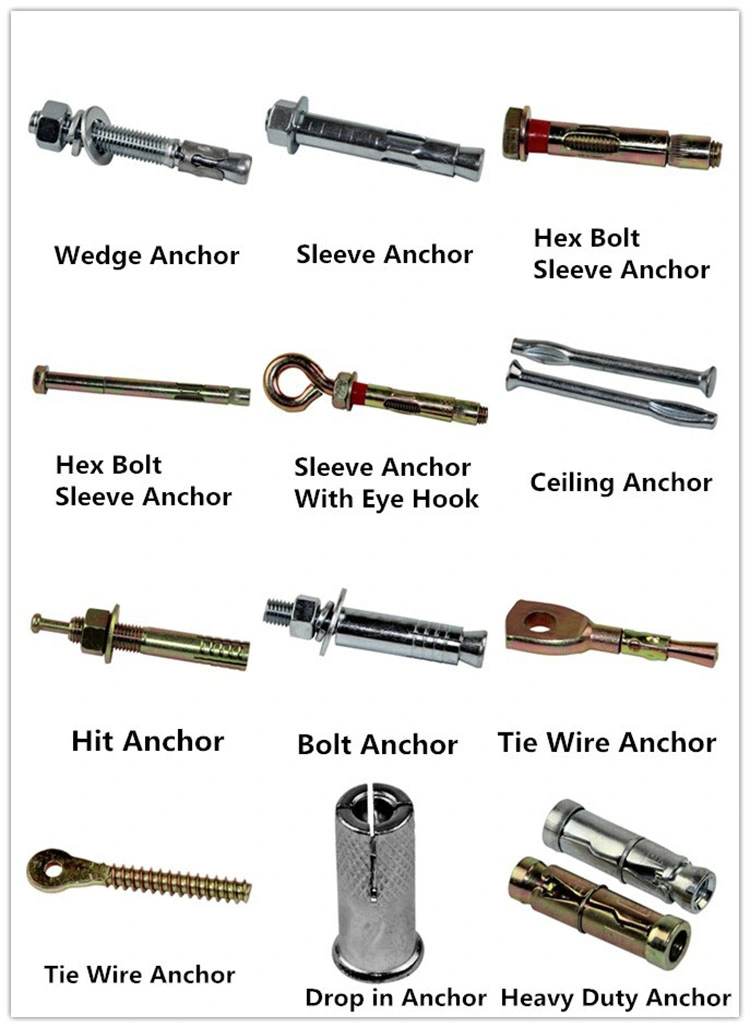

Anchors types

Applications

product descriptions

| Product Name | Sleeve anchor with hex flange nuts |

| Material | 1.Stainless Steel: SS304, SS316 2.Steel: C45(K1045), C46(K1046), C20 3.Carbon Steel: 1010,1035,1045 4.Aluminum or Aluminum Alloy: Al6061, Al6063, Al7075, etc 5.Brass: H59, H62, Copper, Bronze |

| Surface Finish | All kinds of surface treatment are available like chrome plating, zinc plating , nick plating , powder coating, e-coating, dip coating, mirror polishing, etc. |

| Application | Electronic/Appliance/Auto/Industrial equipment metal stamping hardware parts |

| Processing | fabrication, stamping, deep drawing, punching, spinning, laser cutting, bending, seamless welding, machining and assembly |

| Available Certificate | ISO 9001, SGS, Material Certificate |

| Accident Prevention | Safety Operation Management |

Sleeve Anchor FAQ

1. What are the different head styles available?

There are four different head styles, although not all diameters are available in each head style. The head styles are acorn, hex, round, or flat countersunk head.

2. Is the sleeve anchor available in stainless steel?

Yes, it is available with a zinc coating as well as in a 304 stainless steel.

3. Can I get galvanized anchors?

No, these anchors are not manufactured with a galvanized coating. They are only available in zinc plated carbon steel and 304 stainless steel.

4. Do they come preassembled?

Yes, they come preassembled and ready for installation.

5. Do these anchors come with nuts and washers?

Yes, they come preassembled with the correct number of nuts and washers.

6. How do I determine the correct length I need?

To determine what length you need, add the thickness of the fixture being fastened to the minimum embedment for the diameter of anchor being installed.

7. How do I determine the correct diameter of anchor I need?

The diameter of the anchor is determined by the diameter of the hole in the fixture being fastened, by the weight of the item, or the specifications of an engineer.

8.What base material can it be used in?

The anchor is designed for use in concrete, brick, or block.

9. What size should I drill the hole?

The hole that needs to be drilled is the same size as the diameter of the anchor being installed. For example, a ½” diameter anchor requires a ½” hole.

10. Do I need to use a hammer drill to drill the hole into brick?

Yes, the use of a hammer drill is critical when drilling a hole for the anchor.

11. How deep do I install the anchor into the base material?

Each diameter anchor has a minimum embedment depth to ensure minimum holding values.

12. How do I tighten the sleeve?

An acorn and hex nut sleeve is tightened with a standard wrench; the flat and round-headed sleeves are tightened with either a Phillips or flat screwdriver.

13. How far from the curb do I have to put the anchor?

The anchor needs to be installed at least 5 anchor diameters from an unsupported edge.

14. an I use zinc plated anchors in ACQ treated lumber?

No, the zinc plated anchor is not recommended for use in treated lumber.

Packaging and Shipment

Our Market

Our Customers