OEM/ODM China Precast Concrete Rd Threaded Solid Rod Lifting Socket Fixing Anchor with Cross Hole

We are also focusing on enhancing the things administration and QC program in order that we could keep fantastic advantage within the fiercely-competitive enterprise for OEM/ODM China Precast Concrete Rd Threaded Solid Rod Lifting Socket Fixing Anchor with Cross Hole, “Change with the much better!” is our slogan, which means “A greater globe is before us, so let’s take pleasure in it!” Change for that better! Are you completely ready?

We are also focusing on enhancing the things administration and QC program in order that we could keep fantastic advantage within the fiercely-competitive enterprise for China Concrete Directional Lifting Socket and Lifting Socket with High Quality Cross Hole, All of our items comply with international quality standards and are greatly appreciated in a variety of markets around the world. If you are interested in any of our items or would like to discuss a custom order, remember to feel free to contact us. We are looking forward to forming successful business relationships with new clients in the near future.

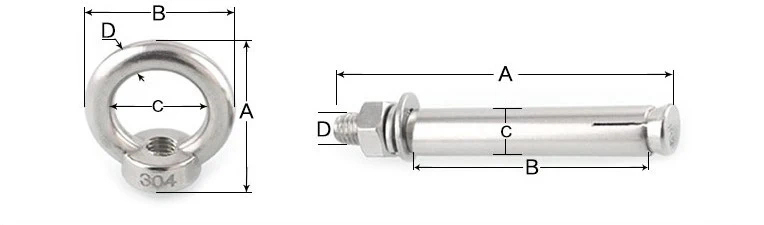

What is steel eye bolt sleeve anchor?

Eye bolt sleeve anchor is a kind of medium-sized preassembled torque controlled concrete mechanical expansion anchor, which is composed of an eye bolt made by cold punching, a cone nut and a pressed carbon steel sleeve. Its expansion function is that the cone nut expands with the upward rotation of the external threads of the eye bolt when tightening , so as to form an expansion mechanism and lock it on the hole wall.

Size

Applications

In addition to fixing objects, sleeve anchor with eye bolt can also be used to hang load objects or let objects pass through eye. It is suitable for various applications of concrete, solid brick or concrete block foundation materials that need connection points.

Installation

▲Using hammer bit and carbide bit, drill a hole in the base materials with the same diameter as the anchor, at least 12 mm to 24 mm deeper than the expected embedment depth.

▲Use a brush or compressed air to remove all debris from the hole.

▲ Align the nut with the top of the sleeve anchor.

▲ Insert the sleeve anchor through the fixture and into the hole of the substrate until the washer and nut are close to the fixture.

▲ Turn the nut until it is tightened by hand, and then turn the hex nut with a spanner, or directly use a hard object to pass through the eye bolt and turn the head clockwise to fix the anchor.

Product Parameters

| Product name | Eye bolt sleeve anchor |

| Standard | DIN, ASTM/ANSI JIS EN ISO, AS, GB |

| Material |

Stainless Steel: SS201, SS303, SS304, SS316, SS316L, SS904L, F593 Steel Grade: DIN: Gr.4.6, 4.8, 5.6, 5.8, 8.8, 10.9, 12.9; SAE: Gr.2, 5, 8; ASTM: 307A, 307B, A325, A394, A490, A449, |

| Finishing | Zinc(Yellow, White, Blue, Black), Hot Dip Galvanized(HDG), Black Oxide, Geomet, Dacroment, anodization, Nickel plated, Zinc-Nickel plated |

| Production Process | M2-M24:Cold Froging, M24-M100 Hot Forging, Machining and CNC for Customized fastener |

| Customized Products Lead time | Busy season:15-30days, Slack seaon:10-15days |

| Stock Products |

Steel:4.8Grade DIN6923, 8.8Grade 10.9Grade of GB5783 and GB5782 Stainless steel: All DIN Standard stainless steel Bolt |

Product Specifications

|

Specification |

Length (L1) |

Case Tube Length (L2) |

Diameter |

Case Tube Diameter |

Hole Diameter |

Wrench Size |

|

M6X50 |

50 |

35 |

6 |

8 |

8 |

10 |

|

M6X60 |

60 |

40 |

6 |

8 |

8 |

10 |

|

M6X70 |

70 |

50 |

6 |

8 |

8 |

10 |

|

M6X80 |

80 |

55 |

6 |

8 |

8 |

10 |

|

M6X100 |

100 |

80 |

6 |

8 |

8 |

10 |

|

M8X50 |

50 |

30 |

8 |

10 |

10 |

13 |

|

M8X60 |

60 |

40 |

8 |

10 |

10 |

13 |

|

M8X70 |

70 |

50 |

8 |

10 |

10 |

13 |

|

M8X80 |

80 |

55 |

8 |

10 |

10 |

13 |

|

M8X90 |

90 |

65 |

8 |

10 |

10 |

13 |

|

M8X100 |

100 |

75 |

8 |

10 |

10 |

13 |

|

M8X120 |

120 |

90 |

8 |

10 |

10 |

13 |

|

M8X150 |

150 |

120 |

8 |

10 |

10 |

13 |

|

M10X60 |

60 |

35 |

10 |

12 |

12 |

17 |

|

M10X70 |

70 |

45 |

10 |

12 |

12 |

17 |

|

M10X80 |

80 |

55 |

10 |

12 |

12 |

17 |

|

M10X90 |

90 |

60 |

10 |

12 |

12 |

17 |

|

M10X100 |

100 |

75 |

10 |

12 |

12 |

17 |

|

M10X110 |

110 |

85 |

10 |

12 |

12 |

17 |

|

M10X120 |

120 |

90 |

10 |

12 |

12 |

17 |

|

M10X150 |

150 |

120 |

10 |

12 |

12 |

17 |

|

M12X80 |

80 |

50 |

12 |

14 |

14 |

19 |

|

M12X90 |

90 |

65 |

12 |

14 |

14 |

19 |

|

M12X100 |

100 |

70 |

12 |

14 |

14 |

19 |

|

M12X110 |

110 |

80 |

12 |

14 |

14 |

19 |

|

M12X120 |

120 |

90 |

12 |

14 |

14 |

19 |

|

M12X150 |

150 |

100 |

12 |

14 |

14 |

19 |

|

M12X200 |

200 |

150 |

12 |

16 |

16 |

19 |

|

M14X100 |

100 |

60 |

14 |

18 |

18 |

22 |

|

M14X120 |

120 |

80 |

14 |

18 |

18 |

22 |

|

M14X150 |

150 |

90 |

14 |

18 |

18 |

22 |

|

M14X200 |

200 |

150 |

14 |

18 |

18 |

22 |

|

M16X100 |

100 |

60 |

16 |

20 |

20 |

24 |

|

M16X120 |

120 |

80 |

16 |

20 |

20 |

24 |

|

M16X140 |

140 |

90 |

16 |

20 |

20 |

24 |

|

M16X150 |

150 |

100 |

16 |

20 |

20 |

24 |

|

M16X200 |

200 |

150 |

16 |

20 |

20 |

24 |

|

M16X400 |

400 |

– |

16 |

20 |

20 |

24 |

|

M20X100 |

100 |

45 |

20 |

25 |

25 |

29 |

|

M20X120 |

120 |

65 |

20 |

25 |

25 |

29 |

|

M20X150 |

150 |

85 |

20 |

25 |

25 |

29 |

|

M20X200 |

200 |

145 |

20 |

25 |

25 |

29 |

|

M20X250 |

250 |

180 |

20 |

25 |

25 |

29 |

Packaging and Shipment

Our Market

Our Customers

We are also focusing on enhancing the things administration and QC program in order that we could keep fantastic advantage within the fiercely-competitive enterprise for OEM/ODM China Precast Concrete Rd Threaded Solid Rod Lifting Socket Fixing Anchor with Cross Hole, “Change with the much better!” is our slogan, which means “A greater globe is before us, so let’s take pleasure in it!” Change for that better! Are you completely ready?

OEM/ODM China China Concrete Directional Lifting Socket and Lifting Socket with High Quality Cross Hole, All of our items comply with international quality standards and are greatly appreciated in a variety of markets around the world. If you are interested in any of our items or would like to discuss a custom order, remember to feel free to contact us. We are looking forward to forming successful business relationships with new clients in the near future.