China Factory Price High Quality DIN1473 ISO 8740 Hollow Round Cylindrical Full Length Parallel Grooved Dowel Pins With Chamfer

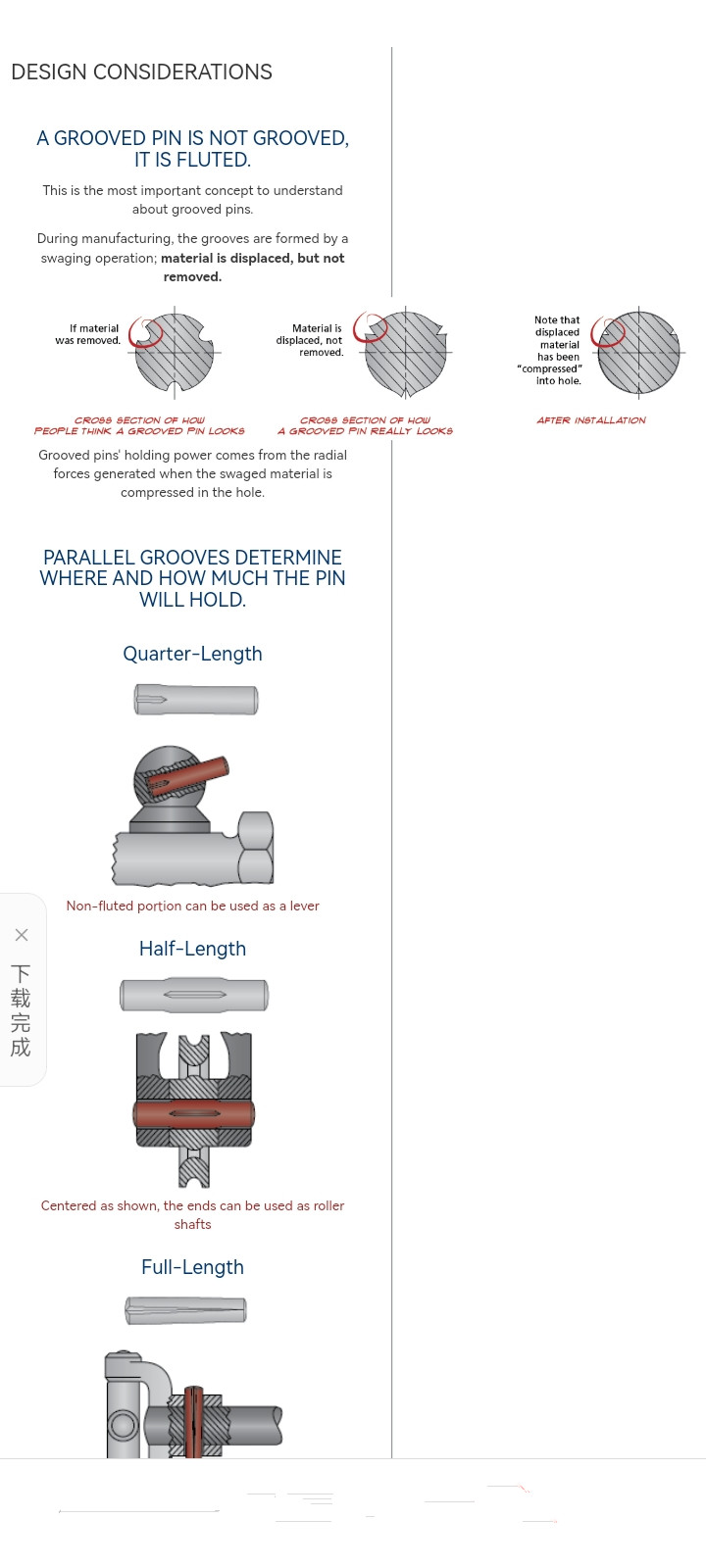

What is grooved pins?

Grooved pins, which feature either parallel or tapered grooves are produced as standard in mild steel or A2 stainless steel, in either half length of full length sizes.

They host a number of advantages, including the fact that they do not need a precision reamed hole, and the fact that they can be grooved on only part of the length.

Size

Applications

The groveed dowel pins are solid pins that are commonly used as a connecting element. When the pin is driven into a drilled hole, the material displaced by the grooving of the pins is forced back to partially close up the grooves and lock the pin into place.

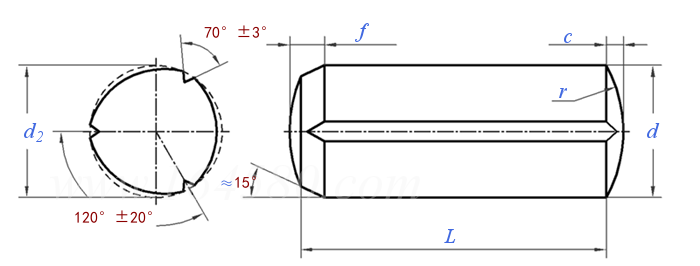

Product Parameters

.

Full Length Parallel Grooved Dowel Pins With Chamfer

| Product Name | Full Length Parallel Grooved Dowel Pins With Chamfer |

| Available Material | 1.Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420,etc. |

| 2.Steel:C45(K1045), C46(K1046),C20,etc | |

| 3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200CuZn37), C28000(CuZn40),etc. | |

| 4.Bronze: C51000, C52100, C54400, etc. | |

| 5. Iron: 1213, 12L14,1215,etc. | |

| 6. Aluminum: Al6061, Al6063, etc. | |

| 7. Carbon steel:AISI1006,AISI1010,AISI1022,etc. | |

| 8.Alloy steel: SCM435,10B21,etc. | |

| Grade | 4.8,5.6,6.8, 8.8, 10.9, 12.9, A2-70, A480 |

| Standard | ANSI / BS / DIN / GB / ISO / JIS / BSW |

| Drive Type | Word/Triangle/Interior Angles Quarter/Cross/M Word/Flower/Cinquefoil/Flower Word/Hexagon/Special Shap |

| Head Type | Pan/Hex/Truss/Oval/Wafer/ Countersunk,etc |

| Surface Treatment | Zn-plated,ni-plated,tin-plated,chrome plated,passivated,sandblast and anodize,chromate,polish,electro painting,black anodize,plain,H.D.G,etc. |

| Certificate | ISO9001:2015/SGS/ROSH/IATF16949:2016 |

| Heat Treatment | Tempering,Hardening,Spheroidizing,Stress Relieving. |

| Application | Mechanical equipment,tele-communications equipments,robot,computer cases and cabinet,electrical appliances |

| Quality Control and Detection Equipment | Our QC department work is inspection and final inspection. We promise you as below: |

| 1. Check the raw material before the production. | |

| 2. Have inspection during the production. | |

| 3. Make 100% inspection before the shipment. | |

| Coordinate Measuring Machine, Calipers, Microscope, Micrometer,DEM, Height Meter and 00 Level Marbel Panel, Ring Gauge, Three Pin, Thread Gauge. | |

| Drawing Format | Pdf/JPEG/Ai/Psd/CAD/Dwg/Step/Igs |

| Machining Equipment | Cold Forging Machine, Thread Rolling Machine, 4-axis CNC Machining Center, CNC Lathe, High Speed Electric Spark Puncher, Milling Machine ,Grinding Machine, CNC Lathes , Wire-cuts, Laser Cuts , CNC Shearing Machines ,CNC Bending Machines, etc. |

| Packaging | PP Ploybags + Standard Carton + Wooden Pallet |

| Delivery Methods | DHL,EMS,UPS or Fedex (fast and safer) |

| Payment Term | L/C, T/T, Escow, Paypal, Western Union, Cash |

| Delivery time | Within 15-20 workdays after deposit or payment received |

| Shipping Port | Tianjin Port |

Something you may worried about

| FAQ |

| 1) What is your main products? |

| Threaded rod, Hex bolt, Hex Nut, Flat washer, Screws, Anchors, Blind rivet, etc |

| 2) Do you have MOQ for your product? |

| It depends on sizes, Usually 200 kgs to 1000 kgs. |

| 3) How about your delivery time? |

| From 7 days to 75 days, depends on your sizes and quantity. |

| 4) What is your payment term? |

| T/T, LC, DP, etc. |

| 5) Can you send me a price list? |

| Due to a lot of kinds of fasteners, we quote prices accoridng to sizes, quantity, packing only. |

| 6) Can you provide samples? |

| Sure, free sampls will be provided |

Packaging and Shipment

Our Market

Our Customers